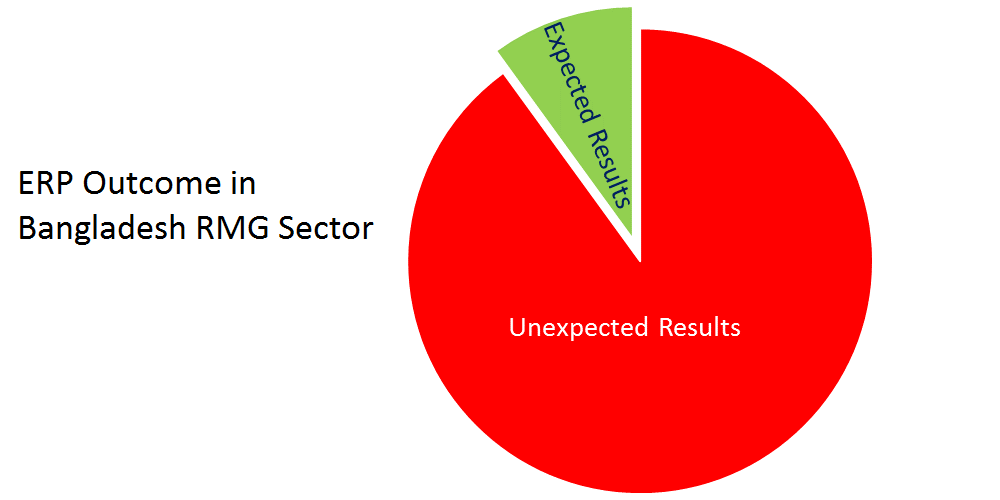

Most of Bangladeshi RMG companies are not getting expected results from ERP

Business Analyst | 03 April, 2019 (Wednesday)View 2431

Bangladesh is the 2nd largest Garment & Textile manufacturing country in the word. Many companies try to implement ERP but most of them fail to get expected results.

All customer Orders are not executed by ERP

ERP is implemented in different Garment companies but those companies can not handle all customer orders by software. Because they

- Fail to identify the actual sales requirements for software

- have not configured the software as per sales requirements

- have not considered all sales scenarios for software

- Fail to streamline information among the sales processes

- Fail to provide business friendly software to people

Therefore, they cannot execute all customer orders through ERP system. And they are not able to control their sales by ERP software.

Development & Supply Chain are not integrated

Development information are not flowing in the supply chain. Because

- Development & supply chain are not connected in a single platform

- Information of development & supply chain are not streamline

- Actual requirements of development & supply chain are not identified

- Software is configured without identifying actual development & supply chain requirements

- All development & supply chain business scenarios are not considered

- Standard processes & best practices (ex. BOM, Routing, MRP) are not following in development & supply chain

As a result, development fails to meet supply chain requirements and supply chain fails to fulfill manufacturing needs. At the end, companies fail to control their development & supply chain as well as production by ERP software

All Material requirements are not generated by ERP

Purchase & production demand cannot be generated automatically since customer orders & development information (BOM, Routing) is not connected. As a result,

- Purchase Orders

- Production Orders

- Subcontract Orders

Cannot be generated automatically from software.

Materials are not availabile on time

Supply chain cannot provide on time material delivery to Manufacturing. Because

- Supply chain & Manufacturing processed are not connected

- Material in-housing plan are not done by following production plan

- Actual material planning & production planning requirements are not input in software

- Material in-housing plan and production plan are not done by one central planning team

- Actual production planning requirements are not visible to procurement of supply chain

Due to actual information invisibility among supply chain & Sales, procurement cannot inhouse material on time. At the end production is hampered. Finally, by using ERP system, Companies are not getting any benefits.

Lack of inventory management

Material inhouse time, availability, material stocks are not visible. Because companies

- Fail to streamline warehousing processes

- Don’t record all received & Issued of materials in software

- Have no policy to count inventory stock in cycle basis

- Fail to realize store people to keep record of all received & Issued of material in software

- Have not established standard warehousing processes

- Have no Inventory control team

Finally, companies are not able to control their inventory by using ERP system.

Incomplete reports generated from system

ERP Software is deployed but standard processes & best practices are not implemented. Sales, Development, supply chain, Warehousing and manufacturing processes are not connected. Therefore, broken processes are existed. Actual requirements are not entered in software and garbage data is available. At the end, management reports cannot be generated with real data.

Users cannot rely & trust on the system

Software fail to provide actual Sales, Development, Supply chain, Warehousing & Manufacturing business data as software is not configured and customized as per actual business requirements. Therefore, People cannot not rely on the software and trust the software data. Finally, People reject the ERP software.

Conclusion

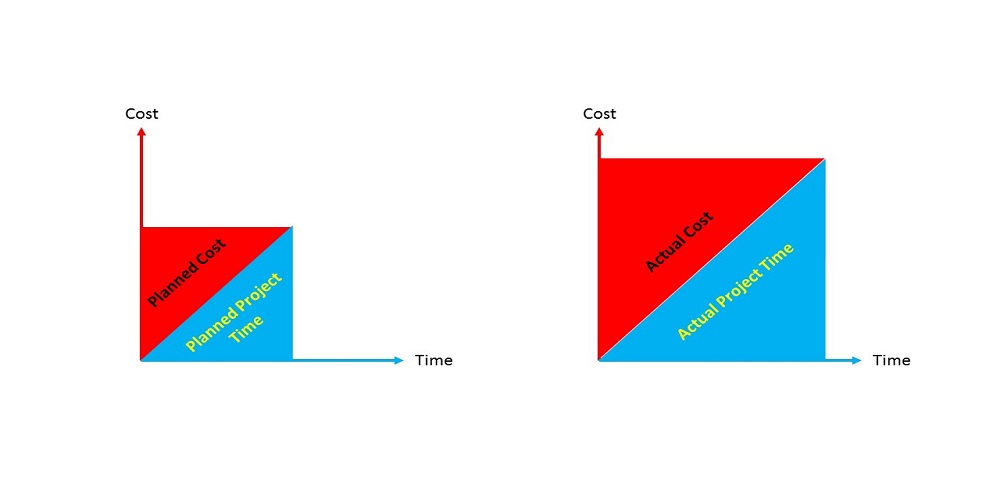

Many RMG companies in Bangladesh implement ERP but they don’t get expected result as software are not comply with actual business requirements. To get control their business by ERP software, companies must identify the actual business requirements and set up ERP software as per business needs.