A manufacturing company will not survive in business, without proper inventory recording

Business Analyst | 11 May, 2019 (Saturday)View 1693

Inventory is the most important part and base of a manufacturing company. If a company can’t control its inventory, it will face huge problem even it will be dropped out from the business. To control inventory, company must have a strong inventory system and record each & every inventory movements accurately. Without accurate inventory information, a company will face bellow problems.

Fail to calculate actual raw material cost

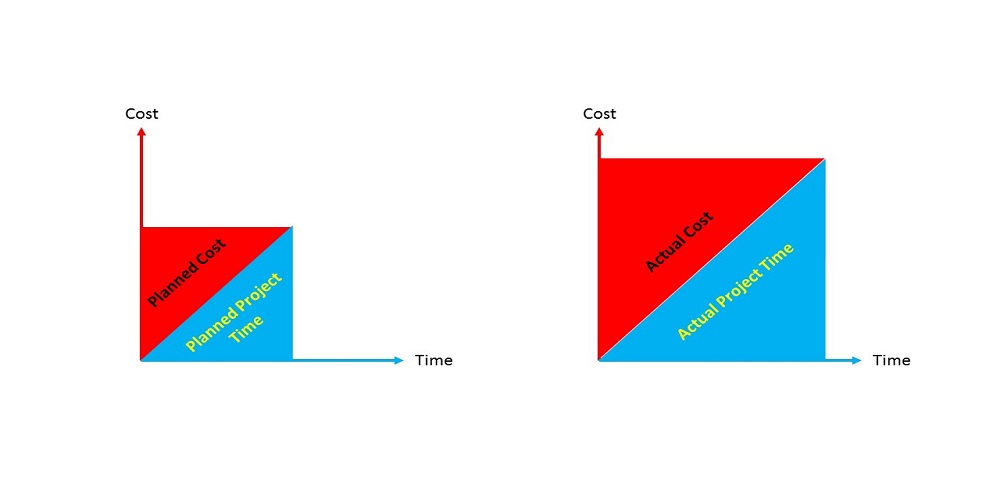

Materials are purchased for producing finished products. Material will be short and excess in production. For material shortage, more materials need to be purchased which is cost extra money than budget. And excess materials become leftover which is the unutilized cost responsible to reduce profit margin. A company will never know the actual material used quantity without proper inventory recording. As a result, company can’t calculate the actual material cost as well as profit & loss.

Fail to calculate actual finished product manufacturing cost

Different manufacturing processes are involved in producing finished products and materials flow in these processes. For example, to produce a garment, yarn is the raw material. This yarn is converted to knitted (white) fabric. By dyeing process, knitted (white) fabric becomes finished fabric. By cutting, sewing and finishing, finished garment is produced. Cost is involved in each and every process. Without recording material & product movements, it’s not possible to calculate the actual manufacturing cost

Read more: Unlock great things by recording material & finished goods movement

Can’t measure supplier performance

A company never be able to follow up & control suppliers without accurate material movements data. As a result, it’s not possible to measure suppliers’

- Delivery performance

- Quality performance

Read more: Business will collapse without 3 things

Never be able to control material flow in production

Without proper inventory recording, it’s not possible to know how much material are

- Provided to production

- Actually, used in production

- Returned from production

- Less or extra used in production

At the end it’s impossible to control material flow in production.

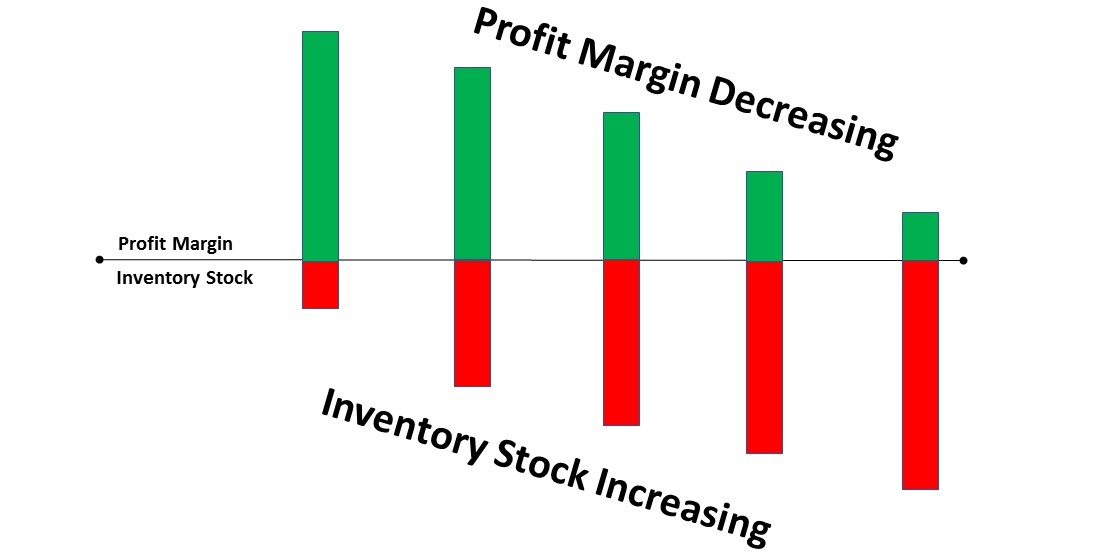

Can’t control inventory cost

If actual inventory stocks are not visible, a company can’t know how much materials are available already. As a result, when gets new orders from customers, company will purchase new raw materials although materials are already available in the store/warehouse. At the end, inventory will be increased day by day and company will fail to control inventory cost.

Fail to provide excellent customer service

A company will fail to provide excellent customer service without knowing accurate inventory data. For example, if a customer wants a product in a short time, company will fail to provide the products due to lack of accurate inventory information, although the products are available in the stores/warehouses. At the end company will lose the order.

Final thoughts

A company never be able to make a strategic decision without knowing stock level. If a company fail to control inventory stock, its business must be collapse. Therefore, each and every material movements must be recorded accurately on time. To record inventory, company must need to use ERP software.