ERP project WILL be failed, if a manufacturing company fail to take ownership of the project

Business Analyst | 15 February, 2020 (Saturday)View 1852

According to a renowned analyst firm, about 70%-75% ERP projects are failed in 1st world countries. What’s about in Bangladesh? May be in Bangladesh, it is about 90%-95% or even more. Most of the manufacturing companies in Bangladesh are getting failure in ERP projects as companies don’t take the project ownership of the project. They just rely on the ERP vendors. At the end, ERP vendors make money and manufacturing companies get shit from the projects.

About 95% success depends on the company’s strategy

ERP success depends on the implementation strategies that must have taken by a company. A company must be strategic on ERP project and should know which will be the best strategies of this multi millions of dollars project. Company should take below decisions

- How ERP will be deployed, by big bang or phase by phase?

- How many functional departments will be connected by ERP?

- How many implementation phases are needed?

- How many modules are needed to cover selected business areas?

- Which module of ERP will be started first?

- What will be responsibilities of top management?

- What will be the project team structure?

Those decisions must be taken by company not by ERP vendor as ERP vendor is not the right one to take those decisions. If a company fail to take those decisions, ERP will fail on that company

Read more: ERP Success or Failure — 90% responsibility goes to the Company who uses ERP

ERP fails when you don’t choose the right one!

ERP vendor can’t ensure success

Success of ERP depends on how ERP software satisfy business processes. If an ERP software fails to fulfill business requirements, manufacturing company will not get the expected results from ERP. To integrate ERP software with business processes, two things must be done

- Identify actual & complete business requirements

- Ensure ERP system comply with business requirements

Those two things must be performed by manufacturing companies not by ERP vendors. A manufacturing company knows its business processes, cultures & people than any one of outsides. ERP vendor never be able to integrate the business processes with ERP software fully. Only a manufacturing company can ensure the integration of ERP software with business processes.

Read more: Who can ensure success of ERP implementation

ERP project goes over budget without proper planning

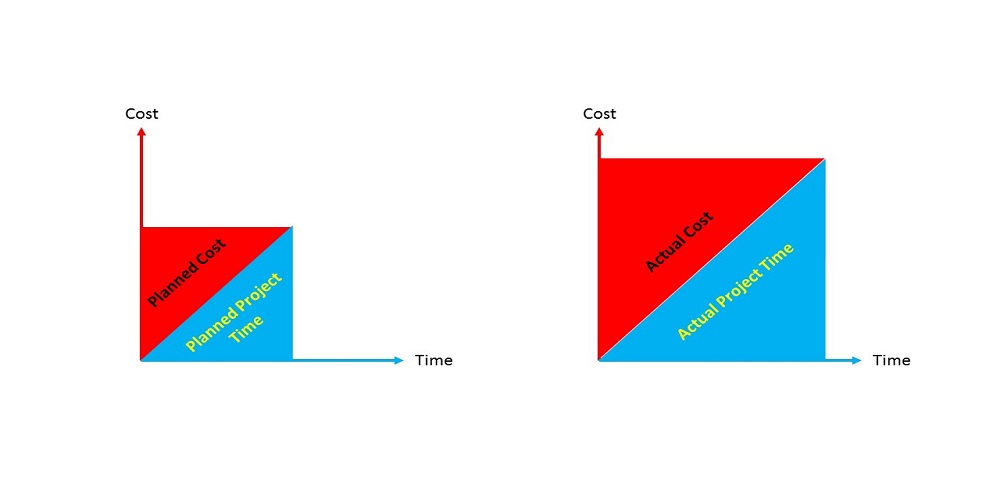

ERP project is very expensive & risky as it implies big change and covers lots of business processes, people, cultures & technologies. A company must understand about ERP project scopes and need a strong plan to handle this multi millions project and minimize risks. Without proper planning, ERP project cost will be hundred times more than the budget and project time line will be longer. The main cost is consultancy cost. About 70% cost of ERP project is consultancy cost. If a company does not have a strong project plan and depends of Vendors’ consultants, vendor will make much more money than expected.

Read more: ERP Cost Breakdown

Control the vendors’ consultants to minimize project cost

A manufacturing company must have a plan to control the vendors’ consultants. Company must make the to-do list of vendors’ consultants. To configure & customize the ERP software, company should not depend on vendors’ consultants rather than company must have a smart project team to handle the configurations & customizations. If company performs those by its own, about 50%-60% will be reduced than expected project cost.

Read more: How to minimize ERP implementation cost

Final thoughts

A manufacturing company should not decide to start an ERP project without a complete project plan & budget. Without a complete project plan, company never be able to take the ownership of the ERP project. If company fails to take ownership of the project, it will not get expected results from ERP and able to control the project cost. At end, millions of dollars project will become a billion dollars project. Remember that Vendors consultants never be able to ensure success.