Can't manage your suppliers without a good Inventory Management

Business Analyst | 23 February, 2020 (Sunday)View 2119

Raw materials carry about 80% cost in manufacturing companies. Raw materials are purchased from suppliers. A manufacturing company will fail to manage its’ suppliers without controlling material flows from suppliers. To manage suppliers, it must need to record all purchase orders, and also record material flows from suppliers to manufacturing company and manufacturing company to suppliers. Without recording materials flow, a manufacturing company will

Fail to follow up & control Purchase Orders

Without consolidating the purchase orders data with material receiving & return records, it not possible to know

- how much materials are ordered?

- how much are received?

- how much are returned to supplier?

- how much are still pending to receive?

- how many orders are closed or open?

Without that information, it’s not possible to follow up & control its’ suppliers

Read More: Unlocked many great things from Inventory Mangement

Can’t find out delivery performance

A manufacturing company can’t evaluate delivery performance of suppliers without knowing

- How many orders’ materials are received on time?

- How many orders’ materials are received in delay?

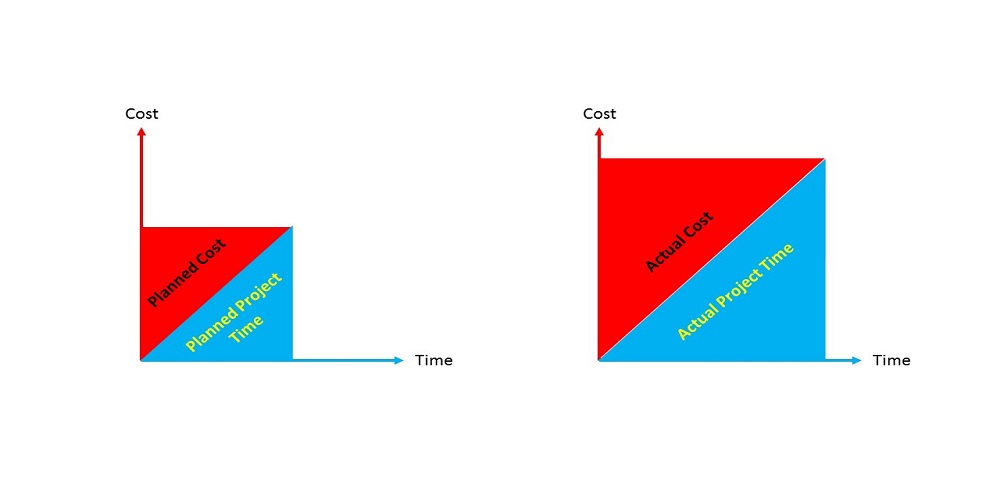

- What are the planned lead times?

- What are the actual lead times?

Read More: A manufacturing company will not survive in business, without proper inventory management

Fail to find out quality performance

Without below information, it’s not possible to find out quality performance of suppliers

- How much materials’ quality is passed?

- How much materials’ quality is failed?

- What are the defect rates?

Without that information, company cannot claim suppliers for bad quality materials and renegotiate with the suppliers or find new suppliers.

Can’t generate receiving reports to know material receiving status

Without recording material receiving accurately, its’ not possible to create

- Material receiving report

- Material order status report

- Quality report

- Stock balance report

A company can’t know the material receiving status from suppliers without those reports

Can’t know exact Business with suppliers

Without exact receiving data, it’s not possible to know

- What’s the value of ordered materials?

- What’s the value of received materials?

- What’s the value of returned materials to supplier?

- how much value of materials are still pending to receive?

If a company does not have those data, it can’t make accurate payment to suppliers.

Conclusion

To mange suppliers and pay them based on receiving and quality, a manufacturing company must have a good warehousing & inventory management. Without recording each & every material movements, warehousing & inventory management will not work. So it must need to record each & every material movements to manage the suppliers.