What is ERP and how does it work?

Founder & CEO, Pulse 366 | Enabling AI for Business Leaders | Global Management Consultant | IPE, BUET | 16 March, 2020 (Monday)View 3501

ERP is not just a software.

ERP stands for Enterprise Resource Planning.

Enterprise means the whole organization including all functions and processes.

Resources are Manpower, Machine, Space, Material, Time, Money etc. that are used to produce the products or services.

Planning is like Production Planning, Material Planning, Cost Planning, Capacity Planning, Sales Planning etc.

These 3 words do not mean anything like software.

Actually, ERP is a concept, a management style, a way of planning.

I am going to explain it below.

Yes, you will need help of computerized tools in order to establish ERP.

But those tools are like helpers, not like operators.

ERP means a lot of lists. And those lists are gold mines!

When different users record information, it creates a lot of lists.

Such as list of products, list of orders, list of inventories, list of suppliers, list of transactions etc.

When you record all your customer orders in one place, it creates an Order List.

Later, when you record all your sale deliveries in one place, it creates a Delivery List.

If you combine Order List and Delivery List, you get an Order Shipment Report.

From the report, you can see the percentage of on-time delivery.

You can identify which orders/models/styles has poor performance.

You can also identify which step causing delay for a particular product.

Then you can take improvement decisions and that will work like a charm.

This is how you can improve your organization by taking advantages of lists.

This is the ERP way of managing the company.

Without looking at list, taking decisions based on idea and assumptions will lead to waste of time, waste of money and waste of energy.

ERP is for Planning. ERP is nothing without Planners.

As explained above, ERP means a lot of lists.

But those lists are not valuable without planners.

Planning can be realistic only if you have all the information in hand.

For example, to make a production plan, you need the order list, you need inventory list, you need routing step list etc.

Without these lists, the plan can never be realistic.

When the plan fails, market share will be lost, inventory will increase, resources will be wasted, business will collapse.

Same goes for sales plan, material plan, delivery plan etc.

Therefore, you need planner who will create all the different plans looking at all necessary lists.

This is the ERP way of making plan.

If you don't have planners, then the lists are almost useless.

ERP adds the highest value if lists are recorded in 2 stages

A company uses its resources to produce higher value products and services.

Resources are always limited and should not be wasted.

That's why we need to make plan before using the resources.

For example, we need to make capacity plan before using the capacity.

We need to make material plan before purchasing.

We need to make financial plans before spending money.

The "R" in "ERP" represents "Resources".

Therefore, ERP helps to record the usage of the all the resources.

Such as, how much material was used, how much time (capacity) was used, how much manpower was used etc.

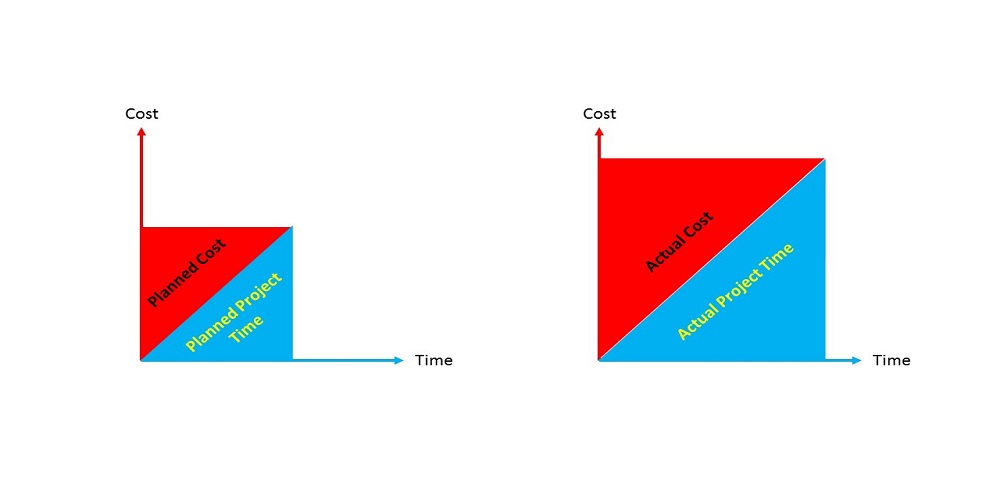

But these quantities of resources must be recorded in 2 stages.

- While making plan - Standard/Planned Quantities

- While using - Actual Quantities

Comparing Planned and Actual Quantities, you can get the variance.

Variance is the base of all improvements.

Looking at variances - you can minimize wastes, maximize resource utilization, reduce costs and increase profits.

Looking at variances - you can provide better customer service, get more market and make more sales.

This is how ERP adds the highest value.

If you record only Actual Quantities and if you don't record Standard/Planned Quantities, then the true ERP can never be achieved.

Your ERP should be doing more.

Software provides common platform to store and retrieve information.

It makes document processing easier.

It offers many more features.

But that's not enough to be ERP.

It is supposed to do more.

Hope this article helped you to realize that.

----------------------

#ipebulbul #360BA

#ERP #OerationsManagement #BusinessAnalysis