Unlocked many great things by recording the received & issued (Stock Transaction) processes.

Business Analyst | 21 January, 2019 (Monday)View 2555

Received & Issued processes (Stock transactions) are very easy and simple processes of warehousing. By controlling these processes, many great things can be unlocked. To control the processes, each & every transaction needs to be recorded. By recording the transactions, below reports will be generated

By using the reports, below great things can be unlocked.

Read more: You are losing money if you don’t have Stock transaction records

Supplier follow up & control

Consolidating the Purchase Order data with transaction data, we can get how much materials are ordered, how much are received, how much are returned to supplier & how much are still pending to receive and how many orders are closed or open. If we have the all information, we can follow up & control the suppliers in better & efficient way. In fig: 1 For purchase order#155, out of 500 Kg, 350 Kg material is received where 100 Kg is returned to supplier due to bad quality and still 250 Kg material is pending to receive.

Supplier Delivery Performance

We can find out how many order’s materials are on time and how many are delay, what are the planned lead times & what are the actual lead times from purchase orders & transactions data. By that information, we can evaluate the supplier based on delivery performance.

Supplier Quality Performance

By checking the quality of received material, we can know how much materials are passed and how much are failed, what are defects. Using that information, we can also claim supplier for bad quality materials and renegotiate with the supplier or find new supplier.

Material Utilization & Inventory control

We can also control our stock by knowing how much materials are issued to production & how much are utilized, how much are excess or shortage. From Stock transaction report, 350 Kg raw material was issued to production, but this quantity is not utilized fully, therefore, 10 Kg material is in stock.

Production Order follow up & Control

Consolidating the production order & stock transaction data, how much materials are needed in production and when those are needed, how much are issued for production, how much are shortage or excess in production? All the activities can be following up & control by comparing production data with stock transaction data.

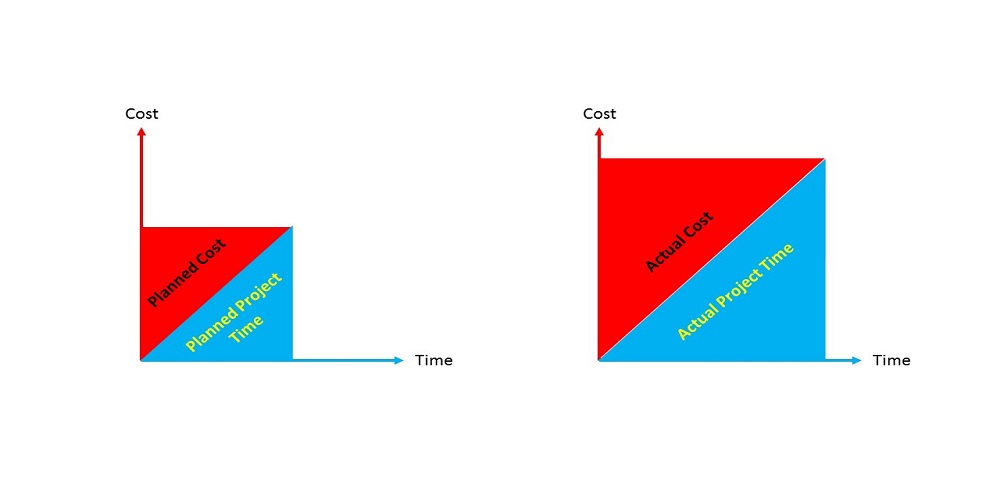

Standard vs Actual Process Loss

From bill of material, we know the required raw material quantity and wastage. And we can know the actual material utilized quantity in production. By comparing the required & actual utilized material quantity, actual process loss can be calculated. Then we can know, our company is gaining or losing money.

To know about Bill of material, read this article: Bill of Material; You are losing money if you don’t have it

In conclusion, unlocking all of the great things is possible to control cost and manage company by highest level of efficiency, if each & every transaction is recorded with accurate data on-time. To record all stock transactions, we need a warehouse management system as every day there are thousands of transactions are happening and it’s not possible to memorize those. When there is a transaction, we must have to record the transaction immediately. Otherwise, we can’t control the stock transaction as well as cost.