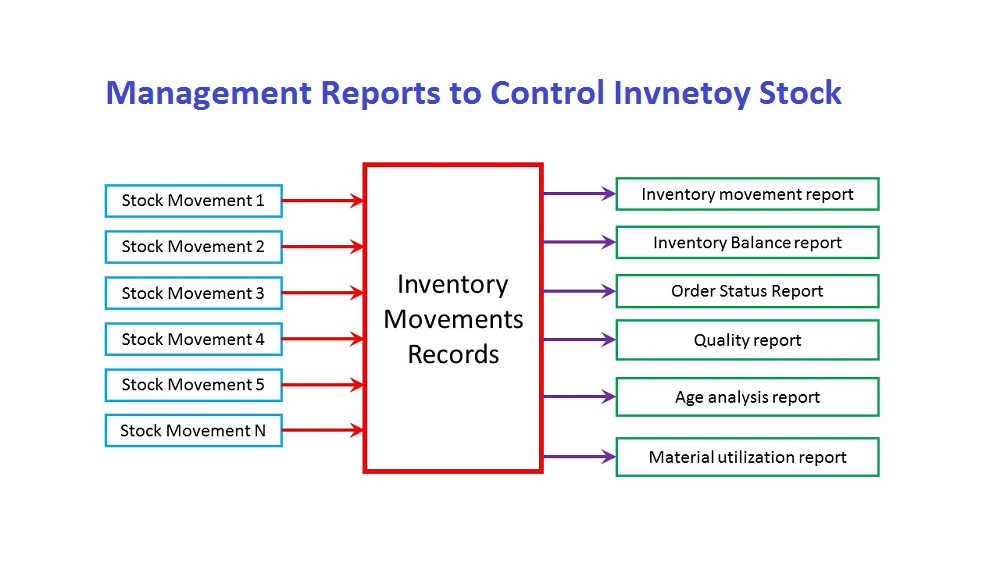

Management reports for Inventory Control & Warehousing

Business Analyst | 02 March, 2020 (Monday)View 2347

Management reports for Inventory Control & Warehousing

There are three kinds of inventory stock are available in a manufacturing company. There are

- Raw materials

- Work in process

- Finished goods

To know inventory stocks condition, below reports are very helpful for management

Inventory movement/transaction report

This report is the key for any inventory & warehousing report. Without this report, no inventory report can be generated. From this report, you can see raw materials/WIP/Finished goods quantity

- Receive, issue, return, transfer & shipment etc. wise

- Location, Zone & movement date time wise

- Internal & supplier lot no, specifications wise

- Sales order/Work Order/Project & Purchase Order no, supplier & customer wise

This report is generated from inventory movements information.

Inventory Balance report

This is another key report. From this report you can know the available stock in store or warehouse and production floor. This report shows the available raw materials/WIP/Finished goods stocks

- Customer wise

- Item wise

- Factory unit wise

- Location & zone wise

- Supplier wise

- Internal lot wise

- Sales order/Work order/Project & Purchase order wise

This report is generated from inventory movements information.

All other reports are generated from Inventory movement/transaction report & Inventory Balance report. If information is wrong in those reports, other reports will be populated with wrong information.

Read More: Unlocked many great things by recording inventory movements

Order Status Report

This report carries Sales order/Work order/Project wise raw materials/Finished goods, Item, Customer & Factory unit wise

- Order quantity to supplier

- Receive quantity from supplier

- Return quantity to supplier

- Pending received quantity from supplier

- Received quantity from other areas

- Total received quantity

- Issued quantity to production & other areas

- Return from production & other areas

- Total Issued quantity etc.

This report is generated from Inventory movement/transaction report, Inventory Balance report and supplier purchase order reports’ information. Purchase order report is used by procurement which is consolidated list of all purchase order information.

Quality report

This report is generated from quality checking information. From this you can see How much inventory stocks are

- Good quality and can be usable

- Average quality and can be used after reprocessing

- Bad quality and rejected?

Without this report, it’s not possible to take decision to use raw materials/WIP/Finished goods.

Age analysis report

This report shows the time period of the inventory stocks. How long raw materials/WIP/Finished goods are staying in stores or warehouses. From this report, you can know how long your company is carrying inventory stock and spending money to hold those. At the end, you can take decision for a strategy to reduce the inventory holding time & stock and save money & business.

This report is generated from Inventory movement/transaction report, Inventory Balance report.

Material utilization report

From this report, you can see Sales order/Work order/Project wise raw materials/Finished goods, Item, Customer & Factory unit wise how much materials are

- Issued to production

- Return from production

- Utilized in production

- Extra or shortage used in production

- Unused leftover

From this report, you can know what is the condition of business. You are saving money or spending extra.

This report is generated from Inventory movement/transaction report’s information.

Material receiving report

This report is generated for seeing the receiving inventory stock by daily, weekly, monthly, quarterly & yearly as per requirements. It is populated from Inventory movement/transaction report

Read More: Fail to control inventory Stock, business fails to survive in the market

Inventory valuation

Beside stock quantity, you need to know the value of the inventory stocks. Because at the end, everything is converted in to money to know the business condition. Without knowing the value of inventory stocks, you cannot take decision about your business. From inventory valuation to know what is the

- Purchased order amount

- Value of receiving material

- Value of material used in production

- Value of unused leftover

- Value of rejected materials/WIP/Finished goods

- Value of delivered finished goods to customer

- Value of extra purchased materials

You can get the monetary flow in your company by inventory valuation.

You don’t need to generated extra report for inventory valuation. Just add price & value in all reports then you can see the material flow with money in those reports.

Key things to generate those reports

All those reports can be generated & will be workable if each & every material movement is recorded accurately on time. Without on time recording with real data, those reports will not provide accurate information about inventory stock. As millions of inventory movements are occurred, ERP system is needed to capture that information.